Headquartered in Romanengo in the province of Cremona, northern Italy, Ferrarini & Benelli design and manufacture equipment for corona surface treatment and plasma 3D treatment.

Highly skilled and qualified personnel take care of product design, software programming, and engineering in-house, enabling F&B to develop bespoke solutions to meet specific customer requirements.

Through close cooperation with the major manufacturers of converting equipment, Ferrarini & Benelli have over 10,000 treaters installed around the globe.

Corona surface treatment increases the adhesion of inks, adhesives, lacquers, and other coatings used in the processing of flexible packaging materials. Ferrarini & Benelli have developed specific treatment systems for the following applications:

- Blown Film Extrusion: single or double-sided treatment for LDPE, LLDPE, HDPE, and multi-layer structures. View Our Video Here

- Cast Extrusion: high-speed single and double-sided treatment for OPP, CPP, BOPP, and PE.

- Sheet Extrusion: single and double-sided treatment for rigid and hollow sheets.

- Foil Extrusion: single and double-sided treatment of semi-rigid foil or foam.

- Pipe Extrusion: a patented system for internal surfaces for district heating systems and improvement of the bonding of polyurethane foam.

- Laminating and Coating: to improve the bonding of adhesives with or without solvent and with water-based systems. View Our Video Here

- Flexographic and Gravure Printing: to improve the bonding of adhesives with or without solvent and with water-based, UV, and EB systems. View Our Video Here

- Narrow web: for printing labels and adhesive tapes.

- No-noise Effect: to guarantee no-noise effect for adhesive tapes.

- Production of Cables, Pipes, Sections: to increase surface tension and improve the bonding of inkjet printing or adhesives.

- Panel Production: corona treatment for sheet metal panels

Click Here to Download Our Brochure

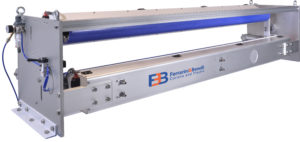

Bikappa Rotary Corona Treatment

Cartonplast Corona Treatment for rigid sheets

Dyne Tests Pens and Corona Markers

Poliplast Corona Treatment Station treatment station for non-conductive plastic film

Polimetal Corona Treatment Station for the treatment of plastic and metallised film.